In today’s fast-paced manufacturing world, efficiency, consistency, and hygiene are paramount. Automatic packaging machines have become the unsung heroes of countless industries, revolutionizing how products are prepared for market. These machines automate the process of placing items into containers, wrapping them, or sealing them within protective materials, dramatically increasing output while reducing labor costs and human error.

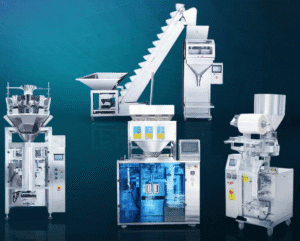

Here is an overview of several primary types of automatic packaging machines and their applications.

1.Vertical Form-Fill-Seal (VFFS) Machines

The VFFS machine is a ubiquitous and highly versatile workhorse. It forms packaging from a roll of flat film, creating a bag around the product. The product is weighed and dropped into the forming bag, which is then sealed and cut off.

Typical Products: Suitable for a vast range of free-flowing and non-free-flowing items. This includes snacks (chips, nuts), powders (coffee,奶粉), granular products (rice, seeds), hardware (screws, nails), and fresh produce.

Speed: Extremely fast. Speeds vary based on product and bag size, but typically range from 20 to 120 bags per minute (bpm), with some high-speed models exceeding 200 bpm for simple products.

2.Horizontal Form-Fill-Seal (HFFS) Machines

Unlike VFFS, HFFS machines form pouches horizontally. They are ideal for more complex packaging shapes and for placing multiple items neatly into a single pack. They often integrate with cartoning systems.

Typical Products: Perfect for bundling multiple units. Commonly used for cookies and crackers, chocolate bars, frozen foods, tea bags, medical devices, and small toys. They excel at creating “tray-and-lid” style packaging for ready meals.

Speed: Generally slightly slower than VFFS due to more complex motions, but still very efficient. Common operating speeds are between 40 and 90 packs per minute.

3.Multihead Weighing Packaging Machine

The Multihead Weighing Packaging Machine, often called a combination weigher, is the heart of modern, high-speed packaging lines where extreme accuracy meets maximum throughput. This sophisticated system is engineered to handle free-flowing products—such as snacks, frozen vegetables, nuts, confectionery, and hardware items—by combining the weighed portions from multiple scales into a single, perfectly measured dose.

Typical Products:This system is perfectly suited for packaging a wide variety of free-flowing and semi-free-flowing dry goods, including: Snacks & Confectionery, Frozen Foods, Staples & Ingredients, Hardware & Industrial Items

Speed: For lightweight snacks like chips or pretzels, speeds often reach 50-100 bags per minute. For heavier or non-free-flowing items, the speed remains impressive at 30-60 bags per minute

In conclusion, the choice of automatic packaging machine is dictated by the product’s nature, the required packaging material, and the desired output speed. From sealing fresh food for safety to bundling goods for retail display, these automated systems are fundamental to modern production, ensuring products reach consumers efficiently, securely, and in perfect condition.