With the acceleration of modern life, “fast food” has become increasingly popular among young people. Consequently, the surge in fast food packaging has drawn consumer attention to the quality and safety of the plastic films and bags used for food packaging.

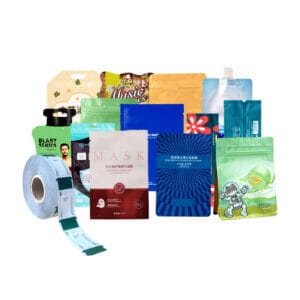

Types of Packaging Films and Bags

Plastic food packaging films and bags primarily serve to protect food from external chemical and physical factors—such as microorganisms, oxygen, moisture, and temperature—thereby preserving freshness, flavor, and extending shelf life. They provide essential support during transportation and distribution.

These packaging materials are mainly categorized into two types: single-layer (non-composite) and multi-layer (composite) films or bags.

Non-composite films are made from a single type of polymer resin—such as Polyethylene (PE), Polyvinyl Chloride (PVC), or Polyvinylidene Chloride (PVDC)—and are used for products like cling wraps and resealable bags. PE is common for vegetable wraps and snack bags, while PVC, though clear and strong, is unsuitable for oily foods, microwave use, or high temperatures. PVDC is often used for packaging cured meats and cooked foods.

Composite films combine two or more materials—such as different plastics, paper, or aluminum foil—using various lamination techniques. Examples include aluminum-plastic composite bags for snacks and aseptic paper-based composites for liquid foods like milk. These multi-layer structures meet requirements for aesthetics, printing, and functional barriers, making them ideal for a wide range of products including instant noodles, biscuits, candies, and dairy products.

Key Safety Indicators

The safety of plastic food packaging depends on four critical aspects:

- Mechanical Properties

These ensure the packaging can withstand handling, transport, and storage. Poor mechanical strength can lead to breakage, causing food spoilage, contamination, or loss.

- Barrier Properties

This refers to the material’s ability to block oxygen, water vapor, odors, or oils. Proper barrier performance is crucial for determining shelf life. For instance, oily foods require high oxygen and grease barriers, while fresh produce may need some permeability to gases.

- Biological Safety

Packaging must be free from microbial contamination such as mold or bacteria, which can proliferate in humid storage conditions. Using microbially contaminated packaging poses direct health risks.

- Chemical Safety

This is a vital factor, involving potential migration of harmful substances into food. Risks include heavy metals, toxic monomers, or residual solvents from the manufacturing process. Poor packaging design or material selection can also lead to chemical migration during storage or use. Manufacturers must not overlook mechanical and barrier performance in pursuit of chemical and biological safety, as functional failures can also endanger food quality.

Practical Tips for Consumers

To avoid unsafe packaging, consumers can:

* Smell: Avoid packages with a strong or pungent odor, which may indicate solvent residues.

* Scratch: Gently scratch printed surfaces; low-quality prints may rub off easily.

* Inspect: Check for delamination or poor sealing in composite bags.

* Choose Wisely: Opt for packages with less vivid printing, as brightly colored inks may contain harmful substances that could migrate into food.

In summary, ensuring the safety of plastic food packaging involves understanding material types, key performance indicators, and adopting simple, practical checks when selecting products.